Unleashing Power and Portability: The Indispensable Trailer Pump

Whether it's pumping concrete to elevated heights, dewatering a construction site, or moving sludge in environmental cleanup operations, the right equipment can make all the difference. Enter the trailer pump, a versatile and powerful solution that brings mobility and high performance together.

Defining the Mighty Trailer Pump

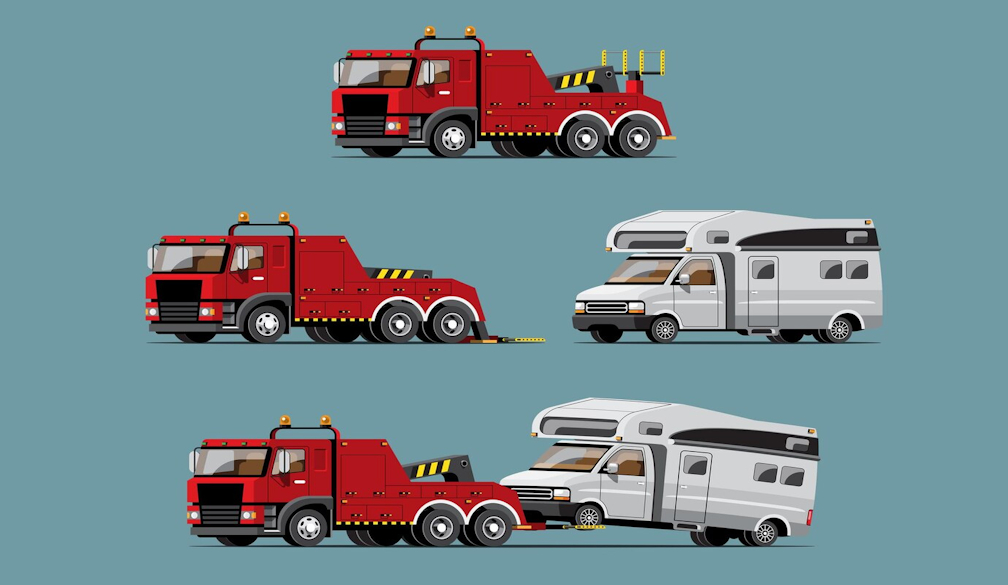

So, what exactly is a trailer pump? Simply put, it's a powerful pump mounted on a towable trailer. This ingenious design allows for easy transportation from one job site to another, making it an incredibly flexible asset for various applications. Unlike stationary pumps, the trailer pump offers the advantage of being readily deployable wherever the need arises. These pumps are engineered to handle a wide range of fluids, from thick concrete mixes and abrasive slurries to clean water and sewage. The core of a trailer pump lies in its robust pumping mechanism, which can vary depending on the specific application. Common types include piston pumps, screw pumps, and centrifugal pumps, each offering unique advantages in terms of pressure, flow rate, and the type of fluid they can handle.

The Diverse Applications of a Trailer Pump

The versatility of the trailer pump is one of its most compelling features. You'll find these workhorses tackling a multitude of tasks across various industries. In the construction sector, the trailer pump is indispensable for concrete placement, especially in high-rise buildings, bridges, and tunnels where traditional methods are impractical. Its ability to pump concrete vertically and horizontally with precision saves time and labour. Beyond construction, trailer pumps play a crucial role in dewatering flooded areas, mines, and construction sites, ensuring safe and efficient operations. They are also vital in environmental applications, such as pumping sludge and wastewater in treatment plants and during cleanup efforts. Furthermore, agricultural operations often utilize trailer pumps for irrigation and the transfer of liquid fertilizers. The adaptability of the trailer pump makes it a go-to solution for any situation requiring the movement of significant volumes of fluid.

Why Choose a Trailer Pump? The Advantages are Clear

Opting for a trailer pump comes with a host of benefits. Foremost is its portability. The trailer-mounted design allows for quick and easy transportation, eliminating the need for specialized hauling equipment in many cases. This mobility translates to increased efficiency and reduced downtime between projects. Secondly, trailer pumps are known for their power and reliability. They are built to withstand demanding conditions and deliver consistent performance, even when handling challenging fluids. This robustness ensures longevity and minimizes the risk of project delays due to equipment failure. Moreover, the versatility of a trailer pump means that a single unit can often handle multiple tasks, reducing the need for a large fleet of specialized pumps. This can lead to significant cost savings in the long run. Finally, modern trailer pumps often come equipped with advanced control systems and safety features, enhancing operational efficiency and ensuring the well-being of the operators.

Selecting the Right Trailer Pump for Your Needs

Choosing the ideal trailer pump requires careful consideration of several factors. The type of fluid you need to pump is a primary concern. Concrete pumps, for example, are specifically designed to handle the abrasive nature of concrete, while pumps for wastewater may require different seals and materials. The required flow rate and pressure are also crucial considerations. You'll need to determine the volume of fluid that needs to be moved within a specific timeframe and the pressure required to overcome any resistance in the system. The distance and height to which the fluid needs to be pumped will also influence the selection process. Furthermore, consider the power source available at the job site (diesel or electric) and any specific regulations or environmental concerns that might impact your choice. Consulting with experienced trailer pump suppliers and understanding the specific requirements of your application are essential steps in making an informed decision.

Maintaining Your Trailer Pump for Optimal Performance

Like any piece of heavy machinery, a trailer pump requires regular maintenance to ensure optimal performance and extend its lifespan. This includes routine inspections, lubrication of moving parts, and timely replacement of worn components. Following the manufacturer's recommendations for maintenance schedules and procedures is crucial. Proper cleaning after each use is also essential, especially when pumping abrasive materials like concrete. Regular checks of hoses, connections, and seals can help prevent leaks and ensure safe operation. Investing in regular maintenance for your trailer pump will not only keep it running smoothly but also prevent costly repairs and downtime in the long run.

Conclusion: The Power of Portable Pumping

In conclusion, the trailer pump stands as a testament to the power of combining performance with portability. Its versatility, reliability, and ease of transport make it an indispensable tool across a wide range of industries. From the towering skylines built with the help of concrete trailer pumps to the dewatered construction sites ensuring progress, these machines play a vital role in shaping our world. Understanding the capabilities and advantages of a trailer pump is key to maximizing efficiency and achieving success in any project requiring the movement of fluids. So, the next time you see a trailer pump on the road or at a job site, remember the power and versatility it brings to the task at hand.