Revolutionary new Aussie technology could have seen quarantine accommodation built in just 18 hours

- Written by Tess Sanders Lazarus

Three dimensional concrete printing (3DCP) technology by Melbourne-based company Luyten has been proven to be capable of printing a complete fully functional set of units in just 18 hours. This groundbreaking technology doesn’t come with the price tag you might expect either, costing a fraction of the cost compared to traditional construction.

Cofounder and CEO of Luyten, Ahmed Mahil, said, “Using this technology, the cost of a quarantine project could be lowered by 80 percent in comparison to traditional construction, and 55 percent compared to prefabricated solutions. Ready to be fitted with utilities and plumbing, these accommodation facilities would be aesthetically pleasing and liveable within just a couple of days. The months, and even years, some projects can take to be constructed is now redundant – the new age of construction is upon us.”

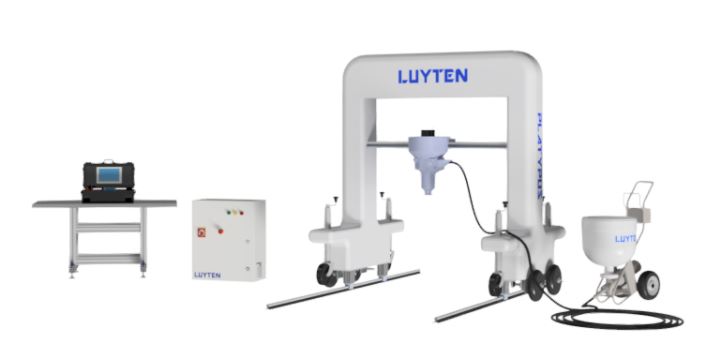

Founded in 2020, Luyten’s mission is to bridge the technological gap in large-scale construction and manufacturing industries through the introduction of robust construction automation technologies such as cutting-edge 3D printing and additive technologies. The company design and manufacture custom large-scale three dimensional construction printers. The entrepreneurs and cofounders behind Luyten are Ahmed Mahil, Dr Godfrey Keung (Chief Scientific Officer), Michael Stanley (Chief Technology Officer) and Shaun Heap (Chief Information Officer).

“When COVID-19 hit the world, Ahmed, Godfrey, Shaun and I collectively recognised that the passion project we had been working on for all of these years could have saved countless lives. Our original three-dimensional concrete printing solutions could have built more hospitals or quarantine accommodation in a matter of days or weeks rather than months at the height of the pandemic, and for a fraction of the price,” Stanley said.

“Our technology is bringing to the table the opportunity for the construction industry to become more financially feasible than ever before in history. The Luyten Platypus mobile 3D concrete printer is at the forefront of the fourth industrial revolution – it is the first mobile gantry and commercial ready concrete printer in Australia and the southern hemisphere,” Dr Keung added.

According to Mahil, the construction industry is at a tipping point. After a century of being stagnant, LUYTEN’s 3DCP, which started out as a passion project between university mates, now has the capacity to shake up the industry unlike anything the world has seen before. Just as Ford changed the game with model T in the second industrial revolution, Luyten has changed the game with the PLATYPUS mobile 3D concrete printer. The affordability of the Platypus will make it an essential part of the equipment tool kit that small and large construction companies use.”

“The four of us formed a friendship throughout our talks to do with construction. All this whilst Godfrey, Ahmed, and Michael undertook their PhD candidatures at Monash University throughout the mid-2010s. Godfrey, Ahmed, Michael and I developed greater interest through our casual discussions about the global housing crisis, climate change and the lack of automation in the construction industry. We started researching together and meeting on our weekends to dive deeper into these issues,” Heap explained.

“Over the last four years these meetings became more and more regular, which is when we all committed to identifying the issues within the construction industry, and attempting to automate it. The four of us then concocted our own unique solution, which has manifested into our current company Luyten.

“Luyten transforms construction projects that traditionally take months or years to complete, and finishes them within a number of days. The 3DCP revolutionary technology reduces 60 percent of construction waste, 70 percent of production time, and 80 percent of labour costs when comparing hands-on construction projects. In addition, the technology is proven to increase construction site efficiency with 60 percent guaranteed costs savings, 300 to 500 times shorter execution times, and an 80 percent total reduction in monetary expenses without formwork in concrete construction. The world has never seen capabilities like this before.

“We are the first start-up of its kind in the southern hemisphere. Luyten has a number of unique selling points that are also unmatched internationally, such as its capacity to incorporate acoustic and optical based artificial intelligence for data driven concrete printing. Our invention also has a patented anti-clogging printer head, which means that the technology can produce state-of-the-art results time after time.”

According to Mahil, a focus area that has surfaced throughout the last ten years in the construction industry is the environmental impact of the sector’s practices.

“When forming Luyten, we were cognisant of the construction industry’s carbon footprint, and determined to create construction solutions for generations to come that reduce emissions. Our unmatched technology employs up to 40 percent less carbon dioxide emissions through propriety mixes that reduce use of cement, and the robotic systems reduce construction site and logistics carbon dioxide footprints by 50 to 70 percent,” Mahil added.

Luyten designs and manufactures custom large-scale three-dimensional concrete printers that cater for all project needs on site from conceptual design through to the final product. The business offers 3DCP solutions for the incorporation of three dimensional membranes on traditional construction sites, as well as on-site concrete printing consultations, operational assistance, and rental service offerings. Luyten is already in advanced talks with overseas businesses keen to utilise the technology.

3D concrete printing was presented as one of the approaches to address climate change and propagate green technology at the latest climate summit called for by US President Biden.